Innovative Techniques In Swimwear Production

Explore the latest innovative techniques in swimwear production. Learn about cutting-edge swimwear fabrics, eco-friendly practices, and the best case studies that are redefining swimwear manufacturers' collections.

Swimwear fashion is a dynamic and ever-evolving industry, reflecting not only style but also advancements in technology and production techniques. In recent years, the market has seen a significant transformation, driven by innovation in swimwear fabrics, manufacturing processes, and ecological consciousness.

Fabric Innovation: The Second Skin

The foundation of any swimwear line is the fabric. Advancements in textile technology have led to the development of materials that are not only more comfortable and durable but also eco-friendly. A standout example is the introduction of biodegradable fabrics, which decompose within five years after disposal, minimizing environmental impact. These fabrics maintain the elasticity and comfort expected from high-quality swimwear, making them a popular choice for both manufacturers and consumers.

Another significant innovation is the development of 'smart fabrics.' These materials can react to changes in temperature or environment, offering UV protection or thermal insulation when needed. This adaptive feature enhances the swimwear experience, catering to a wide range of climates and conditions.

Sustainable Production: Eco-Friendly Swimwear

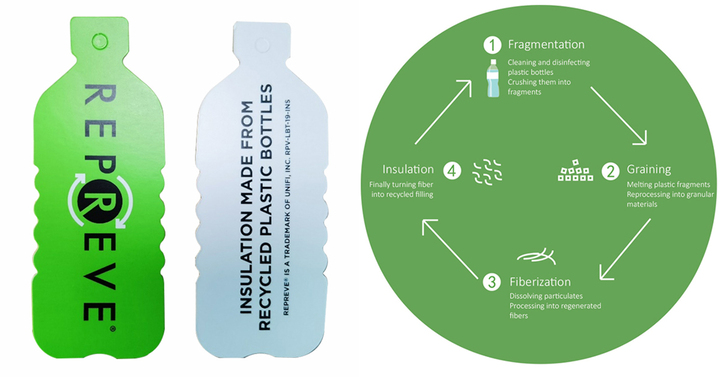

Sustainability is no longer a niche market but a significant trend in the swimwear industry. Brands are increasingly adopting sustainable practices throughout their production chain. From using recycled plastics to create polyester blends to implementing water-saving dyeing techniques, eco-conscious manufacturers are leading the way in reducing the fashion industry's carbon footprint.

Case studies from leading brands such as Patagonia and Mara Hoffman showcase the successful integration of sustainability and style. These brands not only use innovative materials but also champion fair labor practices and transparency in their production processes.

Manufacturing Techniques: Precision and Personalization

3D printing technology has revolutionized prototyping and production in swimwear manufacturing. This technique allows for precise customization, rapid prototyping, and the ability to produce complex designs that were previously unattainable. It also reduces material waste, as products are printed based on demand, avoiding overproduction.

Laser-cutting is another technique that has gained popularity. It offers unmatched precision, allowing for intricate patterns and details that elevate the aesthetic of the swimwear. This process also speeds up the production cycle, enabling designers to bring their collections to the market faster.

The Digital Shift: Swimwear in the Age of E-commerce

The rise of e-commerce has pushed swimwear manufacturers to adopt innovative digital solutions. Virtual fitting rooms and AI-based size recommendation tools help reduce returns and increase customer satisfaction. Brands are also leveraging social media platforms to create immersive digital campaigns that showcase their innovative collections to a global audience.

The swimwear industry is at the forefront of innovation, embracing new fabrics, sustainable practices, and advanced manufacturing techniques. By learning from the best case studies, manufacturers can not only create a swimwear collection that stands out for its style but also its commitment to innovation and sustainability.

What's Your Reaction?