More than Just Spandex: The Science of Racing Swimsuit Fabrics

Discover the high-tech fabrics powering Olympic swimmers. This guide explores the types and functions of professional racing swimsuits, from hydrophobic coatings and strategic compression to carbon fiber technology.

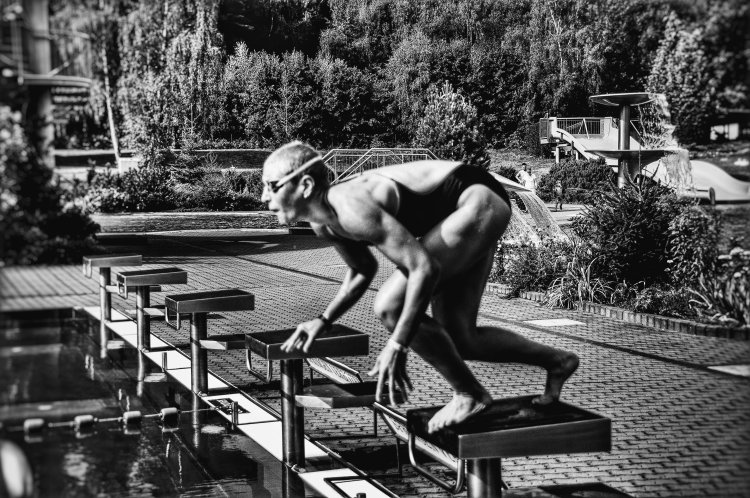

In a sport where victory is measured in hundredths of a second, every detail matters. Swimmers dedicate years to perfecting their stroke, turn, and dive, but in the modern era, they have a powerful ally: their swimsuit. Long gone are the days of simple wool or nylon briefs. Today's professional racing suits are marvels of textile engineering, designed with one purpose: to make the human body faster in water.

But what exactly are these suits made of, and how do they work? It’s not just "tight spandex." It’s a sophisticated blend of materials and construction methods designed to tackle the three main enemies of speed: drag, muscle oscillation, and fatigue. This is a deep dive into the types and functions of the fabrics that are shattering world records.

The Great Reset: Why All Suits Today Are "Textile"

To understand modern suits, we must first look back to the 2008-2009 "super-suit" era. Suits made from non-porous, rubber-like materials like polyurethane trapped air, added unnatural buoyancy, and compressed bodies to an extreme degree. Records didn't just fall; they were obliterated.

In 2010, FINA (now World Aquatics), the sport's governing body, banned these "non-textile" suits. This reset the playing field and forced manufacturers to innovate within strict rules. Today, all approved suits must be made from "textile fabric(s)" and meet specific criteria for thickness (max 0.8mm), buoyancy, and water permeability. This constraint sparked a new wave of innovation, focusing on how traditional textile fibers could be woven and treated for maximum performance.

Part 1: The Types of Racing Fabrics

Modern racing suits, often called "tech suits," are not made from a single material. They are advanced composites.

1. The Core Blend: Polyamide + Elastane

The foundation of nearly every tech suit is a blend of two fibers:

• Polyamide (Nylon): This provides the suit's primary structure. It's lightweight, durable, and comfortable (relatively speaking) against the skin.

• Elastane (Lycra or Spandex): This is the magic ingredient for compression. While a practice suit might have 10-20% elastane, a high-end tech suit can be 30-40% elastane. This high percentage is responsible for the suit's incredible "squeeze" and shape retention.

2. The Construction: Woven vs. Knit

This is the single biggest difference between a practice suit and a racing suit.

• Knit Fabrics: Your training suit is knit. Its fibers are looped together, making it soft, stretchy, and comfortable. However, it's also more porous and absorbs more water.

• Woven Fabrics: Tech suits are woven. The fibers are interlaced at 90-degree angles, like a canvas or a dress shirt. This woven construction is far more rigid, less stretchy (it can take 20 minutes to put on a suit), and less porous. This creates a smoother, more compressive and more durable surface.

3. The "Smart" Fibers: Carbon Fiber Integration

This is where true innovation lies. Brands like Arena have famously integrated carbon fiber directly into the woven textile. This isn't just for looks; the carbon creates a "carbon cage" or grid within the fabric. Other suits may use different proprietary fibers, but carbon is the most well-known. Its unique properties unlock an entirely new level of function.

Part 2: The Functions of Racing Fabrics

So, how do these materials come together to make a swimmer faster? They perform three primary functions.

1. Hydrodynamics: Reducing Water Resistance

The first goal is to make the swimmer as slippery as possible. Woven fabrics are naturally smoother than knit fabrics, but swimwear manufacturers take it two steps further.

• Hydrophobic Coatings: The suit's surface is treated with a powerful Durable Water Repellent (DWR) coating. This makes the fabric hydrophobic (water-fearing). Instead of soaking into the suit, water beads up and rolls off. This dramatically reduces water absorption, keeping the suit lightweight and minimizing friction drag as the swimmer slices through the water.

• Seamless Construction: Stitched seams create ridges that cause drag. On a tech suit, seams are almost always bonded or ultrasonically welded. This creates a perfectly smooth, seamless surface, further streamlining the swimmer's profile.

2. Strategic Compression: Shaping the Body

This is the most noticeable function. The high elastane content and tight woven pattern work together to provide intense, strategic compression. This isn't just about "feeling tight"; it has specific biomechanical advantages.

• Streamlining: Compression "locks" the swimmer's core and streamlines the body, squeezing it into a more optimal, tube-like shape. This reduces form drag, which is the resistance caused by the swimmer's own shape.

• Reducing Muscle Oscillation: When a swimmer moves, their muscles vibrate or "oscillate." This vibration is wasted energy. Compression locks those muscles in place, reducing the oscillation and allowing more of the swimmer's power to be converted into forward motion.

• Improving Blood Flow: Many brands claim this targeted compression helps increase blood flow and oxygenation to key muscle groups, delaying the onset of lactic acid and fatigue.

3. "Intelligent" Compression: The Carbon Fiber Secret

This is the function of the "smart" fibers. The carbon fiber grid integrated into the fabric provides what is called intelligent compression.

The base fabric (polyamide/elastane) is flexible, allowing a full range of motion. However, the carbon fibers woven into it are incredibly stiff and strong. When a swimmer's muscles stretch to a critical point—like during a powerful kick or a wall turn—the carbon grid "locks down" in that specific area.

This provides rigid support exactly when and where it's needed without restricting mobility elsewhere. It’s like a flexible suit that becomes a rigid support system on demand, preventing over-extension and ensuring all power is channeled efficiently.

By combining robust woven textiles like polyamide with high-stretch elastane, treating the surface to be hydrophobic, and integrating advanced materials like carbon fiber, manufacturers have created suits that actively enhance a swimmer's performance. They reduce drag, shape the body, and even think, all within the strict rules of the sport.

What's Your Reaction?